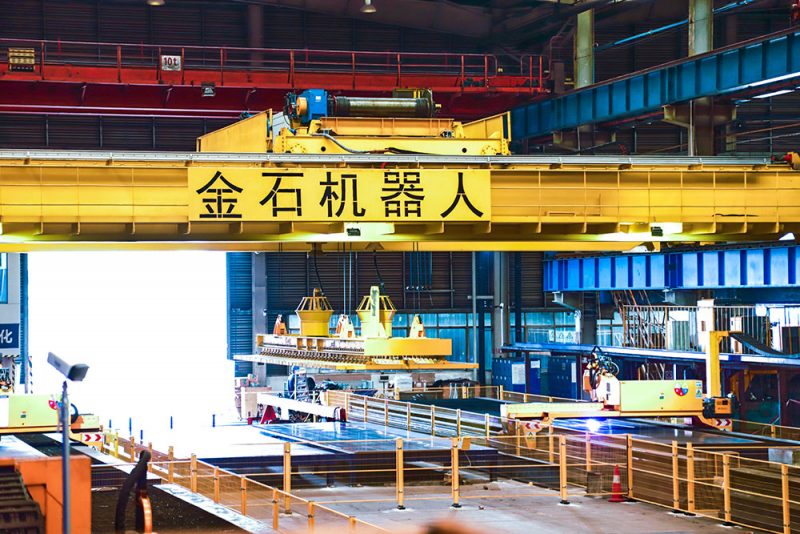

Changsha Equipment Manufacturing Company

This production line is mainly used for the cutting and cutting services of structural sheet metal parts, responsible for the loading of raw materials and unloading and transportation of parts for 8 cutting machines. Realize automatic control of processes such as loading, cutting, cutting, beveling, sorting, and calibration, while also achieving uninterrupted cutting by the cutting machine and dynamic monitoring of cutting information remotely, and have the conditions to access the company's MES management system.

● Steel plate material: Q235, 16Mn, Q490

● Maximum length of steel plate: 10m

● Maximum weight of steel plate: 10t

● Maximum width of steel plate: 3m

● Minimum length> 3m

Automatic picking function for finished products

After cutting the steel plate, the required parts can be selected according to the program specifications.

Improved production efficiency

On the premise of meeting the quality standards for each steel plate part, 8 cutting machines work 28 days a month, 20 hours a day (two shifts), with a production capacity of 6500 tons per month, and an average of 140 plates per day (two shifts).

Full servo drive

Multiple configurations are available for selection, suitable for various industries.