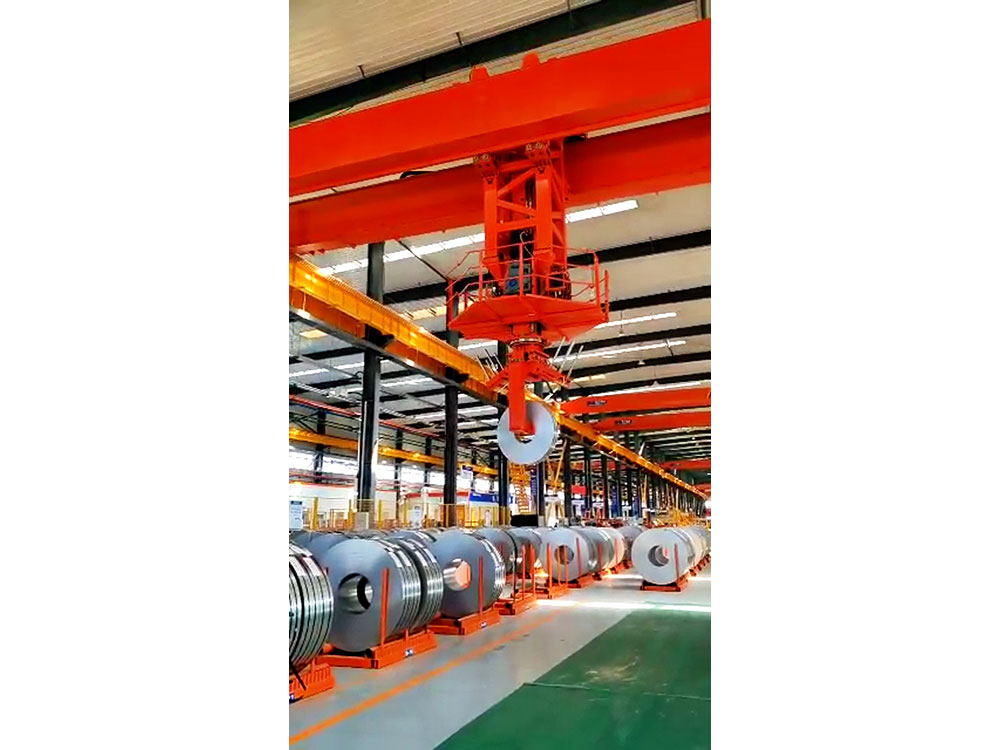

T700 Tianjin factory

Project Background:

● Type of material frame: 1

● Steel coil specification: ≤ 600mm

● Stacking layers: 5 layers

● Cycle average: 2.2 minutes per cycle

Before use:

This project aims to create intelligent lifting equipment for the production workshop of photovoltaic brackets for customers. It adopts technologies such as intelligent warehouse management, precise positioning, automatic control, video monitoring, safety control, and online equipment monitoring to intelligently design two intelligent lifting equipment for the raw material warehouse and finished product warehouse. Realize intelligent operation and centralized intelligent control of lifting equipment in the warehouse area, in order to improve the level of intelligence and informatization and enhance production efficiency.

After use:

The raw material warehouse is designed to store no less than 260 steel coils with a width of ≤ 600mm.

The finished product warehouse design includes 54 L5000 storage spaces, 60 L7000 storage spaces, and 54 L9000 storage spaces, each of which can stack up to 5 layers.